Assembling a pocket laser. How to connect a laser diode, circuit diagram W laser head

Self-assembled laser engraver/cutter based on a 2.5 Watt laser module.

In short - XY-kinematics, Marlin firmware and D8-L2500 laser module. The engraver turned out just right - he knows how to burn, both with dots and lines, and most importantly - to cut!

Let me immediately remind you about TB: when working with a laser, use glasses (special ones, taking into account the wavelength of the laser), do not point it at your eyes. The laser is very powerful - even a small reflected radiation can seriously damage the retina.

So, recently I have been struggling to improve the Neje DK-5 laser engraver in order to increase (primarily) the working area and power for processing various materials. In the end, I came to the conclusion that it would be easier to make another one, in the image of simple Chinese engravers on the profile.

As a basis, I took a Chinese kit on an aluminum structural profile 2020 and 2040. Looking ahead, I will say that practice has shown that it is easier to do everything on the same profile 2040, since the ease of installation and rigidity of the frame significantly increases (it is easier to attach elements of body panels to a double profile , legs, cable channels).

The basis of any laser engraver is the laser module. I had experience working with diodes torn from all kinds of equipment, as well as with a module from Neje, but I wanted something more. The Chinese sell all-in-one solid-state laser assemblies: a module in the form of an aluminum radiator of a cylindrical (less often) or rectangular shape (most often). Inside the radiator there is a cylinder with a laser diode, from which two contacts protrude for connecting the supply current. Also installed inside the laser module (and filled with a certain substance) is a current driver for the diode, most often CC (continuous current), less often a driver with support for TTL signals to control the laser power. Often there is a cooling fan on the side or at the end of the radiator. At the other end of the laser output there is a focusing or collimating lens (depending on the purpose of the module). Power supply is usually 5V or 12V.

Here's an example of what's inside (photo not mine, from the open air).

Solid-state laser modules (diode) range from hundreds of milliwatts (for example, 0.3 W) to several units (for example, 5.5 Chinese watts). The more power, the higher the price, and for powerful modules the price is so high that it is easier to consider installing a CO2 tube, but that is a completely different story. Keep in mind that Chinese watts do not always correspond to reality (it is very difficult to estimate the real radiation power). And you can easily buy the same laser diode, labeled 5.5W, 8W or 10W. Perhaps they will differ in the increased current to the diode itself, which greatly (by several times) reduces the life time of the diode.

Since I wanted to not only burn wood, but also cut anything (plastic, plywood, cardboard, etc. - but not metals!), the Neje module was no longer enough for me, especially since the ones torn from CDs don’t roll, and they burn out quickly. It was decided to look for and purchase a several-watt laser module from China; I mainly chose from 450 nanometer laser modules (one of the most affordable).

There are the following types of laser heads on the girbest:

1. 2.5W 12v;

2. 0.5 W 12V;

3. 0.5 W 5 V.

All lasers are 445nm (violet laser), with cooling fan and power supply included.

In addition to the difference in power, it is obvious that the supply voltage is also different. Modules for 5V are very convenient for power supply with power banks/batteries, as well as for ready-made cases with 5V drives. Don't forget that the fan should also be 5V.

When powering stepper motors from 12V, it makes sense to purchase a 12V laser module in order to unify the power supply for the engraver (that is, you only need 1 12V power supply). This is exactly my option. Included with the D8-2500 is a 12V and 5A power supply, which is clearly enough for the laser diode, and in addition remains to power the Ramps electronics and servos.

In the end, I ordered 2.5W/12V. This is what they sent:

Here are some photos of the laser module itself.

Turned on the laser to check the power circuits and correct connections. Somehow I didn’t realize to install an absorbing substrate, and ended up burning my photophone.

So, I’ll tell you about my engraver project, which resulted in an upgrade of my Neje. A kind of mess from an axe. I twisted the laser and removed the electronics. I realized that you can’t make porridge from this. Replaced electronics and laser. As a result, I decided to leave Neje alone and put it away.

I would like to say that there are ready-made frames for installing lasers - XY plotters. But I decided to assemble the frame myself, especially since it is not so difficult.

The idea was very simple - the use of a 2020/2040 structural profile as a frame and guides for a simple A3 engraver, like in Chinese engravers. Rigidity is ensured by special (standard) connections for the structural profile. (internal connectors, corners). Profile dimensions – dimensions of the printed area (minus the carriage). The format was chosen to be slightly larger than an A4 sheet with the expectation of small-sized materials. After Neje with its 3.5x3.5, the difference is simply huge.

About electronics: there are options for RAMPS/LCD/SD/Marlin or CNCshield/GRBL. I removed the stepper motors from the old device (nema17 - can be purchased, they are standard. Great efforts are not needed, since the laser head is lightweight / I think that with small axes you can use inexpensive nema17 type 17H2408. I ordered a profile cut to size and fittings (corners and hardware), plus rollers for carriages.

In any case, if you are interested in assembling a printer yourself, then there are practically no problems finding drawings for printing on a printer (stl) or drawings for cutting acrylic.

A definite plus of the D8-L2500 laser module kit is the presence of a 12V 5A power supply, which is very convenient. I will power the steppers from the same power supply.

What is required for assembly

1 Laser head Engraver/burner - 1 pc.

2 Power supply 12V For powering the laser and drives (1 piece, included in the kit

laser)

3 5V power supply To power the electronics board (optional)

4 2040 profile longitudinal parts of the frame, X-axis - 2 pieces x 420mm

5 2040 profile transverse parts of the frame - 2 pcs x350mm

6 2040 profile Crossbar Y axis - 1 piece x380mm

7 Nema17 Two in X, one in Y - 3 pcs.

with drive ones not necessarily powerful

gears

8 Belt GT2-6mm Two sections in X, one in Y -1.5 meters approximately

9 Limit switches Extreme positions of X-Y axes - 2 pcs.

10 RAMPS 1.4 Control set - 1 piece (*took everything as a set)

11 Ardu Mega R3 electronics* - 1 piece

12 Display+SD shield+cables - 1 pc.

13 A4988 driver, with radiators - 2 pcs.

14 Set of hardware (screws M3, M4, M5, nuts M3 - Set

M4, M5, T-nuts, washers, etc.) For fastening the frame, straps,

engines, for assembling carriages,

etc.

15 Internal corners For fastening frame corners - 4 pcs.

16 Legs or stands In the corners - 4 pcs.

17 Set of wires -Kit

18 Cable channels** - 1.5 meters approximately

19 Rollers For carriages *** 12 (three carriages of 4 pcs each)

* Electronics can be replaced with Arduino Uno/Nano and CNC shield with drivers (A4988/DRVxxxx)

**There is also a spiral cable channel.

*** You can use 3 rollers, or different rollers (by diameter), depending on the selected carriages.

In terms of hardware, I can only give you an approximate estimate; I took a stock of different denominations, then actually looked at what would fit. I recommend buying in wholesale or ordering from Ali (I ended up spending several times more buying at retail than I would have taken a couple of lots on Ali for 50-100 nuts and screws).

If the carriages are made of acrylic, you don’t have to make a double one - I played it safe, because of this the thickness of the carriage has increased and the working area has decreased by almost 6 cm. You can also take the rollers more conveniently, with a pressed-in M5 bushing.

The original OpenBuilds version assumed the use of only 3 rollers - two running ones and one smaller one for pressing.

To make the carriages lighter, instead of several washers, I used printed bushings. Everything is selected and done in three minutes, and printed in about the same time. You can use washers or make other spacers. When designing, it is better to take into account a small margin in the size of the holes, plus, due to plastic shrinkage.

This is what happened.

Second pass on corrugated cardboard. I made two passes due to the thickness. So cardboard cuts well. Unfortunately, the second order with wire extensions for servos and a cable duct did not arrive in time - I now have a limited work area - the wires are stretched, so there will be no test on a large canvas (well, or I’ll post it later).

A small minus - the work of such an engraver in an apartment is evil))) There is a lot of smoke from cardboard and wood. For this reason, I did not cut plastic and acrylic. Need a good hood.

The plans are to make legs, something like a body, and put the wires into the channels (it is possible to run the wires inside the profile or along grooves, with them secured with clips). Ventilation, exhaust hood and housing are very necessary.

So far the plans are to adapt the laser module to work with PWM by replacing the driver with an external one.

And I'm looking for software to convert images to LCD. What I tried did not help me.

Another thought is that you can add a third axis with a gentle stroke. This will allow for more flexible adjustment to thick materials.

conclusions

In general, the purchase of this module freed up my time, which was spent on altering diodes without housings. There is no need to select a lens and power supply for each one, or shove everything into the body. The cost of the module is quite high, but if you compare the cost of the finished design of a laser engraver of this type, then in the end the benefits are obvious. The fact is that the cost of a laser is more than half the cost of the entire engraver. The rest is the cost of the profile, engines and electronics (little things).

Do-it-yourself laser from a CD-DVD drive

Assembling such a device is no secret to many. This is probably one of the things we collect. DIY laser from a disk drive. It differs from cheap Chinese pointers and other things in that it has a certain power. To make it we only need the basics, and cd or dvd drive.And if it is also a writer, then its power is much greater.

The first thing we will ask ourselves is how remove the diode from the drive.

We disassemble the cutter and take out the optical part. This is what this part of the cutter looks like:

The only valuable things there are the output lens and two lasers. Now we take out the most important thing - the DVD laser:

I ask for your attention:

While you haven't started yet play with a new toy, let me describe the safety precautions for you. Laser from DVD-RW drive belongs to class 3B, which means it is very dangerous for eyesight! Don't point the beam at your eyes and in the mirror! Before you even have time to blink your eyes, your vision will become significantly worse! A guy accidentally showed himself on one forum and ended up with several thousand scams. Consider him lucky. A focused beam can damage your vision even from a hundred meters away! Watch where you shine!

Is it possible to damage a laser diode?? Can! Even very simple. One has only to exceed current and the diode will end. Moreover, a fraction of microseconds will be enough! This is why LDs are afraid of static electricity. Protect LD from him! In fact, the LD does not burn out, the optical resonator inside simply collapses and the LD turns into a regular LED. The resonator does not collapse due to current, but on the light intensity, which in turn depends on the current. You also need to be careful about the temperature. When the laser cools down, its efficiency increases, and at the same current the intensity increases and can destroy the resonator! Be careful! It can also be easily killed by transient processes that occur when turning on and off! It's worth protecting yourself from them.

We take out the laser and immediately wrap a thin strand of stranded wire around its legs so that the LD terminals are electrically connected. We solder a small non-polar capacitor of 0.1 µF and a polar capacitor of 100 µF to its legs and only then remove the core that we wound! This way we will save it from statics and transient processes, which LDs really don’t like!

Now it's time to think about powering our laser. The laser diode is powered by approximately 3V and consumes 200-400mA depending on the power (drive speed). A laser is not a light bulb! Never connect it directly to batteries! Without a limiting resistor, 2 batteries from a laser pointer will quickly kill it! LD is a nonlinear element, so it must be powered not by voltage, but by current! that is, current limiting elements are needed.

This is what the laser looks like from the inside:

So. Now we just need to power our laser. Let's consider several options.

First option.

There will be a current limitation with a resistor, just like a regular diode.

The resistance of the resistor is determined experimentally by the current through the LD. You should stop at 200mA for 16x, further the risk of burning is greater. although my LD worked perfectly at 300mA. Any three batteries of the required capacity will be suitable for power supply. It is also convenient to use a mobile phone battery.

Advantages: simple design, high reliability.

Disadvantages: the current through the LD gradually decreases. And it’s not really clear when it’s time to recharge the structure. Using three batteries complicates the design and makes charging inconvenient.

This circuit is convenient to place in a Chinese lantern, where there is a battery of three AAA (pinky) batteries

The collection will contain the following.

Two 1 Ohm resistors in series and two capacitors.

Second option.

Using the LM317 chip.

In this scheme, everything is much more complicated, and it is perfect for a stationary version of the laser! The driver uses an LM317 chip, which is included with a current stabilizer. The driver maintains constant current through the LD regardless of power supply (at least 7V) and temperature. I advise you to download the datasheet for this chip and understand it more thoroughly, otherwise this is the best driver for the home!

To install on homemade laser module or laser pointer, the printer carriage needs to be modified. And I discovered that the pad from the computer case is perfect for these purposes, and one of them happened to be at hand. Poor guy.

I somehow miraculously managed to bend, trim, drill and finally screw it to the carriage. You just need to be creative and precise. She during this brain assemblies is your faithful companion, but can also be your worst enemy if you neglect her!

The carriage was not at right angles to the scanner table, but luckily for me, a small nut saved the day.

Even before this, I found a small pulley from a cassette player, I installed it on the carriage, but then I realized that it was colliding with the X-axis guide, and I had to remove it. But it's definitely worth keeping it in case of future modifications.

Step 11: Etching the PCB

After successfully testing my prototype, assembled on a breadboard and correctly executing some G-code commands, I began creating a printed circuit board. I have never done such things before, but I am an assistant in a chemical laboratory, so working with chemicals does not cause me any fear.

And used it again for this brainstorming Groover, taking from there the layout of the laser board, which is in the EagleCAD format file.

I mirror-printed this layout on plain paper, glued it onto a photosensitive copper-plated board, and drilled the necessary holes with a Dremel. I don't have a newfangled automatic exposure meter, so I just took some alcohol and removed the protective varnish. Using a contour projector pen and a ruler, I drew the paths by hand. This brain pen leaves a very beautiful shiny mark. I also tried using a German fine permanent marker (acid-resistant), but it produced thick, unsightly lines. And with a contour pen you only had to draw a line once, and not several, and you got a good protective layer.

Etched the board crafts I use ferric chloride (III), I don’t like other available remedies. Some steam, others have a strong smell, and others contain peroxide and can explode if kept in a closed container. Therefore, ferric chloride is the best option for both storage and disposal.

However, DO NOT POUR it down the drain! It will corrode your sewer pipes if they are made of copper and kill all the beneficial bacteria in your septic tank.

Step 12: Laser Shield

I don't know how the pins (that connect to the Arduino pins) are soldered on the back side, so I installed them on the top side of the board and pushed them through.

Just in case, I drew drivers on the board brainlaser where which electrical components should be located. Note: test runs without laser can be carried out without this board.

List of electrical parts

I have attached a list from my order from an electronics supplier, which with all the descriptions looks a little scary.

Note 1:

The supplier made a mistake with the relay in the order, so I had to disassemble the old PC power supply, which I found in my supplies. I am immensely happy with my “stash” of old equipment; most of the electronics are still functioning, and I keep them instead of giving them to a collection point. They sell it to Africa as "second hand", although this is not the case. I built this one brain engraver, to show that “old technology” is not trash. In skillful hands, it is as valuable as money.

Note 2 (important):

When connecting an Arduino with the board installed, make sure to connect the external power supply first. I noticed that when connecting the Arduino to USB, without a connected power source, the steppers start to “scream”, which is not at all cool.

Step 13: Alternative Laser Shield (Easylaser Shield)

Groover's laser shield is great, but there are a few things that don't work with the way I control the laser:

- it cannot switch to the microstepping mode of stepper motors.

The steppers in the DVD he used didn't require this, but if you're using different motors from different units, this option can help you control the motors more accurately.

— I was also not happy with the relay that controls turning the laser on/off.

— and finally, the wires going from the laser shield to the laser were too long, I think it would be more correct to place the shield closer to the laser.

So, to summarize:

I modified the driver from Groover

— moved the driver board, placed it on the terminal clamp for the laser module,

— added jumpers to Easydrivers, thereby activating the microstepping mode.

Upgrade: do-it-yourselfer jduffy54 was kind enough to fix the easylaser board. I updated the layout brain boards, the microstepping jumpers should now work as expected.

Step 14: Laser Diode

The laser diode I used is very powerful. This is a targeted 300mW red class 3 laser, which means you MUST use safety glasses. Otherwise, you can get conjunctivitis and cataracts. It's not like smoking, which can possibly lead to cancer. No, if the beam gets into your eyes, then you are guaranteed to get cataracts. And even the beam reflected from the walls is much more dangerous than if you look at the sun. You don't want to risk your vision. Pause…

BE CAREFUL!!

Safety glasses should not transmit radiation with a wavelength of 600-670 nm (optical density 4+). These glasses are not cheap, but the eyes are priceless!

An optical density of 4+ means 10^-4 of incoming (red) light is filtered.

Eg:

300 mW * 10^-4 = 0.03 mW.

Laser diode pinout:

Having removed a laser diode from an old DVD burner or purchased it on the Internet, the first thing you need to do is determine its polarity. I took two for this brain batteries AA in the case, which are “+” and “-”, respectively, and tried to connect them to the laser diode until it lit up.

The housings of laser diodes such as aixiz contain a heatsink. They often come with a focusing plastic lens. Glass lenses are of course better, as they provide 10-20% more usable power.

Laser diode power setting:

Before you connect the laser to the circuit, you need to adjust the “power” it will receive. This is easy to do using the blue potentiometer.

The red laser from the DVD writer can withstand 300mV (under load - accordingly 300mA), but I don’t know how long it will last.

This means that if you want to increase its service life, you can reduce the power supplied to it to 200 mV (under load - 200 mA).

And I advise you, if possible, to find an old DVD writer, because you don’t want to adjust the power of the laser diode on the laser module used in the craft.

It sounds strange, but for this setup we will use the equivalent of a load that needs to be placed in the circuit instead of an actual laser diode. In this case, you can gradually increase the power, while measuring the voltage, and without the risk of damaging the “precious” diode.

In the photo you can see this very equivalent load, it simulates a red laser. And if you have a blue laser, then you need to use 6 1N4001 diodes.

The equivalent load for a red laser is 4 1N4001 diodes and one 1 Ohm resistor.

for a blue laser - 6 1N4001 diodes and one 1 Ohm resistor.

Again, we take a breadboard and connect diodes and a resistor in series, on which the voltage is measured. It doesn’t matter which side of the diodes you place it on. Set the multimeter to 2000mV and apply the probes to the terminals brain resistor. Next, we connect the wires from the laser driver contacts to the breadboard. Load gcodesender, or the terminal you are using, and connect to the microcontroller. Next, we send the command “M3” (turn on the spindle/laser) and readings should appear on the multimeter.

Then turn the potentiometer clockwise until you get the value you need, for example 300mV. This will correspond to what will be supplied to the laser diode.

CW = boost voltage

CCW = reduce voltage

After this, we send the command “M5” to turn off the laser.

Laser Focus:

To focus the laser, I turned the lens until it became a point on the wall, and then tried to light a match.

To “roughly” adjust the focus, I pasted a ruler on the table and installed a laser next to it, so that the edge of its body was at the 0mm mark. Next, I placed a sheet of black paper in front of the laser and moved it until it lit up. Perhaps you also need to “play” with the lens and the distance of the sheet.

I did the final adjustment of the focal length in a similar way, but this time I calculated how long it would take to burn a hole in the paper. This is how I got the focal length closest to ideal.

Step 15: Soft

Determination of working area:

In the Inkscape editor you need to set the dimensions of the working area. To do this, go to “File” - “Document Properties” and change the page to your size.

One thing you need to know before you start engraving is how to get the gcode for your designs. My choice is Inkscape with a modified Groover Gcodetools (Metalevel 8), which is available on its page.

Before creating a gcode pattern, you need to mirror it. If you just want to select everything and reflect it, this can give strange results in Inkscape.

Therefore, before mirroring, select everything (key combination Ctrl + a), combine it into a group (Ctrl + g) and only then reflect it (‘h’). After mirroring, ungroup (Ctrl + Shift + g) and transform it into a path (Ctrl + Shift + c).

gcodetools needs to be copied to “…\Inkscape\share\extensions”.

But now to get gcode you need to do the following:

1. Ungroup all objects (possibly twice)

2. Ctrl + a (select all) - Path - Object to path

3. Selected all - Extensions - Laserengraver - Laser

4. In the "Preferences" section, select the output folder.

5. Important! Switch to the "Laser" tab

6. Enter the desired speed. It can be overwritten later using Gcodesender.

7. Enter the file name + .nc Then click “Apply” and you’re done!

8. Launch Gcodesender, connect to Arduino and load the .nc file. If desired, change the speed.

9. !!WEAR SAFETY GOGGLES!!

10. Click “Print”

Inkscape cheat sheet

Action Keyboard shortcut

Select all Ctrl + A

Group (group) Ctrl + G

Ungroup Shift + Ctrl + G

Mirror (horizontal) reflect horizontally H

vertical V

Convert object to path (convert to path) Shift + Ctrl + C

Align dialog Shift + Ctrl + A

Fill / Stroke dialog Shift + Ctrl + F

Step 16: He came to life!!!

Some of their carved or engraved works.

Many people had laser pointers as children, which could be purchased in toy stores. But with the development of modern technologies, it became possible to create such a laser with your own hands. To do this, you just need a faulty DVD drive (it is important that the LED itself remains working), a screwdriver and a soldering iron.

It should be remembered that it is better to use a non-working DVD to create a laser! This is due to the fact that after disassembling and removing the LED, it fails. Do not forget that such a laser from a drive is much more powerful than a conventional pointer and can cause irreparable harm to health, so you should never direct the beam at a person or animal.

When the beam of such a device is pointed at the human eye, the retina is burned out, and the person may partially or completely lose vision.

So, let's create a laser from a DVD drive with our own hands. To do this, you need to carefully unscrew the bolts on the back of the case to get to the LED of the future laser. Under the cover there is a unit that drives the carriage. In order to remove it, you need to unscrew the screws and disconnect all the cables. Then the carriage is removed.

Now you need to disassemble it, for which you need to unscrew many screws. Next, two LEDs will be detected. One of them is infrared, it is responsible for reading information from the disk.

You need red, with the help of which information is burned onto the disk. There will be a circuit board attached to the red LED. In order to disable it, you need to use a soldering iron. To check the functionality of the diode, it is enough to connect two AA batteries to it, but it is important to take into account their polarity. Remember that the laser diode is fragile, so you need to be very careful with it.

You need red, with the help of which information is burned onto the disk. There will be a circuit board attached to the red LED. In order to disable it, you need to use a soldering iron. To check the functionality of the diode, it is enough to connect two AA batteries to it, but it is important to take into account their polarity. Remember that the laser diode is fragile, so you need to be very careful with it.

Next, you need to purchase any laser pointer. When creating a laser from a DVD drive with your own hands, use it as a “donor” for the case. After purchase, you need to carefully unscrew the pointer into two parts and remove it from the upper half. You can use a knife to do this. It is important to do everything carefully, because the diode may be damaged. Using a small screwdriver, select the emitter. Using hot melt adhesive, install the new LED into the housing. And to ensure that it is firmly installed, you can use pliers, pressing them on the edges of the diode.

The DIY laser from a DVD drive is almost ready. Before you run it, you need to check if the polarity is correct. Now you can safely connect the power. After the first launch, you may need to adjust the focus. Next, you can install the pointer in the flashlight and connect AA batteries. Do not forget that the laser can burn through various objects, so you need to remove the plexiglass from the diffuser.

A well-tuned drive can not only burn paper or light matches, but also leave a mark on plexiglass, explode balls (it is better if they are black) and leave visible marks on plastic. If you install a diode in the plotter head, you can engrave on plexiglass.

Laser pointers, which many of us played with as children, can be made with your own hands at home. Or you can create a fairly powerful device that can burn objects with its beam. And for this we need a laser diode, which can be removed from the DVD-RW player.

Laser diode taken from DVD

From this article you will learn the sequence of work for creating a homemade laser device with significant power.

What will you need at work?

To make a laser with your own hands, you need to use a red laser diode (650 nm). It can be removed from a broken or old DVD-RW drive.

Note! If the device is broken, then there is a high probability that its laser diode remains in working order. Therefore, it is quite suitable for our work.

You can also use a CD-RW drive. Some even use a Blu-ray drive. But in this case, the CD-RW drive will be characterized by an infrared invisible ray (780nm), and the Blu-ray drive will be characterized by a violet ray (405nm).

In addition, you will also need tools to disassemble the DVD-RW drive.

Let's talk about the player

To remove the laser diode taken from the DVD-RW drive, you need to carefully disassemble the device. To do this, you need to understand drive devices. It is placed in a special metal heat-removing housing, which is additionally placed in another metal base. It depends on you whether it is worth removing the device from such a housing or not.

Note! When disassembling a DVD-RW device, you should not take out the loose discs.

DVD-RW drive

You can also leave the radiator in the case and remove the base. This affects the quality of the heat sink, which is necessary for our laser installation. Some experts argue that when the LED supplies a non-pulse current, the created heat sink will not be enough for the carriage. This statement will be correct for certain drive models, as well as if it is necessary to obtain maximum power.

DVD-RW has two laser diodes built into it. Of these, one is infrared and is used for recording and playing CDs. And the second one is red and is used for playing and recording DVDs. As you can see, if you wish, you can make two lasers with your own hands.

Note! The BD-RE drive model has as many as three diodes built in. But modern models of this type of device use dual LEDs installed on one chip.

In such assemblies, you cannot simultaneously connect infrared and red diodes if the current is large.

Things to remember when working

When creating a laser with your own hands, you must remember that the laser diode can be damaged by static electricity. Therefore, to ensure normal operation of this element, three legs are needed

wrap with bare wire.

Note! Do not direct the laser beam into the eyes. It should also not be pointed at reflective surfaces. This can lead to complete or partial loss of vision.

The requirements that exist for working with lasers are also relevant for infrared radiation. After all, both of these radiations have a powerful burning ability.

Red laser beam

In addition, you need to know that the laser diode must be powered with a certain current. If the supply current exceeds a certain threshold, this may lead to overheating of the diode. As a result, it will either burn out completely or glow like a standard LED.

In order for the current to have the correct values, you need to use a certain laser assembly circuit. In this case, it must have a driver. Let's look at several schemes for assembling a laser using a laser diode taken from a DVD-RW drive.

First build option

In this situation, it is necessary to use the following scheme for assembling a device based on a laser diode removed from the DVD-RW drive.

Assembly diagram

The disadvantage of this scheme is the presence of a situation where the battery voltage sags at the time of discharge, which causes a linear drop in the laser brightness level.

To assemble a laser system according to the above diagram, you need not only a diode, but also capacitors with any voltage (from 3V). In the diagram they are marked with the icon C1 and C2. The capacity of the first capacitor should be 0.1 µF, and the second - 100 µF. They will protect the diode from static electricity and also ensure a smooth transition of processes. Once the capacitors have been connected to the laser light source, the wire can be removed from the lead. When connected to a diode, one of the terminals on the housing will supply a minus. At the same time, the second conclusion will be a plus, and the third one will not apply. The location of the pluses is shown quite well in the second diagram, which will be described below.

It is worth knowing that a plus is supplied to the body of some diodes (for example, 808nm LED). Dual models are characterized by the presence of a middle pin for the common minus (G), and an outer pin - C for powering DVD, CD, D.

This circuit can be powered from a mobile battery or 3 AA batteries.

Note! When assembling the circuit, it is necessary to take into account that the battery voltage may differ from the specified one. This is especially noticeable immediately after charging it. At 3.7 V there may be 4.2 V. In this regard, the battery must be checked with a multimeter.

In this case, the current can also have different values. For example, at the appropriate write speeds of a DVD-RW drive, the laser diode can have the following values of parameters such as power and current:

- at speed 16, the power will be 200 mW, and the current will be 250-260 mA;

- at speed 18, the power will be 200 mW, and the current will be 300-350 mA;

- at speed 20, the power will be 270 mW, and the current will be 400-450 mA;

- at speed 22, the power will be 300 mW, and the current will be 450-500 mA;

- at speed 24 the power will be 300mW and the current will be 450-500mA.

Infrared diode

The infrared diode of the CD-RW drive will have a power of 100-200 mW. For comparison, violet in BLU-RAY RW is from 60 to 150 mW, and in non-writing models - 15 mW.

Before assembling this circuit, when using a DVD drive laser diode, you need to find out what resistance is required for resistor R1. To do this, you can use the formula R1=(Uin.-Ufall.)/I, in which:

- Uin. – voltage coming from the battery;

- Upd. - voltage drop that the diode receives. The red diode should have approximately U drop. equal to 3 V. This voltage is suitable for a low-power non-writing DVD drive. For infrared diode Upad. will be approximately 1.9 V, and for violet or blue - 5.5 V and 4-4.4 V, respectively;

- I - current strength. It can be found out from a special table.

When assembling a laser, many experts recommend using resistors with a higher resistance than what was obtained in the calculations. This will protect the semiconductor from excessive current. Using a multimeter, you can further reduce the resistance.

Second assembly option

In this case, when assembling the laser system, you must be guided by the following diagram.

Laser installation diagram

This scheme, unlike the one described above, does not have problems with a decrease in laser brightness. This problem was solved by using in the circuit

a special adjustable stabilizer (for example, KREN12A or its common analogue LM317T). In this case, you need to know that the selected stabilizer is compensatory. It supplies about 1.4V more voltage than required. As a result, in order to get 3 V to the laser diode in the circuit, you need to apply from 4.4 V to 37 V. In this case, the output will still be 3 V (of course, provided that the resistors are correctly selected).

If less than 4.4 V is supplied to the circuit, the laser brightness will begin to decrease, which is typical for the first circuit. As a result, a situation similar to a battery discharge will arise. For 780nm diodes, the circuit will need to be supplied from 3.8 V to 37 V. Therefore, in such a situation, this circuit may be ineffective, since the current-voltage characteristic here will fluctuate greatly depending on the ambient temperature. And this can lead to a burnout of the circuit if the increase in current value cannot be detected in time.

Note! Some experts believe that this effect is characteristic of blue laser diodes.

To avoid overheating, it is necessary to measure the current before the light source is completely warmed up. This will eliminate the risk of increasing the maximum permissible current value.

Experts recommend using resistance for R1 in Ohm value. And to determine the parameter R2, you must use the following formula: R2=R1*(Uout.-Uref.)/Uref.

You should know that initially R2 should be set slightly less than the figure obtained during the calculations. In this case, you should simultaneously connect a multimeter in series to the diode to evaluate the current strength. This will avoid the occurrence of excessive current.

In this circuit, it is possible to use the same capacitors as in the previous one. But the resistors should be of better quality, especially their connections. If the contact breaks (open circuit) during operation of the installation, the LED diode will burn out due to the increased voltage.

Focusing the light flux into a beam

When creating a laser installation and using a diode removed from a DVD-RW drive, you need to understand that the emitted light will be similar to a standard LED.

LED glow

But we need a laser beam. To make it, you need to use a collimator - a special lens. With its help, the light flux will be focused into a beam. An excellent solution would be to use a lens taken from an old laser pointer in the device. By installing it using nuts and springs, it will be possible to more accurately focus the laser (its approach and distance). The lens can also be attached to the laser diode using epoxy glue or double-sided tape.

Due to the fact that it is not always possible to find a powerful diode, in this situation it is recommended to use the 808nm model.

Getting the green ray

Using a crystal of a certain color, you can produce a laser beam of green, yellow, red and blue.

Conclusion

Using a laser diode removed from a DVD-RW drive, you can create a laser installation with your own hands. Using various crystals, you can focus the beam and give it the desired color. In this case, it is necessary to take into account the peculiarities of working with such a device in order to obtain the desired result and not deteriorate your vision.

Recommended articles on the topic How to assemble a power supply with regulators with your own hands Review of wireless street lights with motion sensors

Why you should pay attention to microwave motion sensors

Why you should pay attention to microwave motion sensors

Probably everyone has had a dream since childhood to have their own powerful laser capable of burning through steel sheets, now we can get one step closer to the dream! Sheets of steel will not be cut, but bags, paper, and plastic are easy!

For our laser, we first need a broken or not very good cutter! and DVD-RW. The higher the DVD-R recording speed, the more powerful the laser is! 16 drives contain 200 mW red lasers, as well as an IR laser, but more on that later.

Disassembling the cutter,

take out the optical part. This is what this part of the cutter looks like:

The only valuable things there are the output lens and two lasers.

Now let's get to the most important thing!

And now safety precautions for you and for the laser!

DVD-RW laser belongs to class 3B, which means it is dangerous for your eyesight! Do not point the beam at your eyes! You won’t even have time to blink your eyes before you lose your sight! a guy accidentally showed himself on one forum and ended up with several thousand scams. Consider him lucky. With a focused beam you can blind from a hundred meters away! watch where you shine!

How can you ruin an LD?

Yes, very simple! Exceed the current and it's over! and a fraction of microseconds will be enough!

This is why LDs are afraid of static electricity. Protect LD from him!

In fact, the LD does not burn out, the optical resonator inside simply collapses and the LD turns into

regular LED. the resonator collapses not from current, but from light intensity, which in its

The queue depends on the current. You also need to be careful about the temperature. when cooling the laser

Its efficiency increases and at the same current the intensity increases and can destroy the resonator! Be careful!

It can also be easily killed by transient processes that occur when turning on and off! from

they are worth protecting.

Now let's continue disassembling the drive))

We take out the laser and its radiator, and immediately solder a small one to its legs.

a non-polar capacitor of 0.1 µF and a larger polar one! so we will save

it from statics and transient processes, which LDs really don’t like!

Now it's time to think about powering our laser. The LD is powered by approximately

from 3V and consumes 200mA. A laser is not a light bulb!! never connect

it directly to the batteries! without a limiting resistor they will kill him and

2 batteries for laser pointer!! LD is a nonlinear element, so power it

You don't need voltage, but current! that is, current limiting elements are needed.

Let's look at three LD power supply schemes from the simplest to the most complex.

All circuits are powered by batteries.

1 option

current limitation by resistor. see picture

The resistance of the resistor is determined experimentally by the current through the LD.

It’s worth stopping at 200mA, further the risk of burning is greater.

although my LD worked perfectly at 300mA. any three will do for food

battery to the required capacity. It is also convenient to use the battery from

mobile phone (any).

Trial run

Having connected the power, we see a consumption of 200mA and a beam of bright light.

In the dark it works like a flashlight.

Focus lens

The beam turned out to be not “laser” at all. You need a lens to adjust the focal length. For starters, a lens from the same drive is quite suitable.

Through the lens it is possible to focus the beam, but without a rigid body the task is tedious.

Case manufacturing

I came across a description on the Internet where people used laser pointers or a flashlight as a body. Moreover, there are already lenses there. But, firstly, we did not have a laser pointer of the required size on hand. And, secondly, it would increase the budget of the event. And I already said that for me personally this reduces the pleasure from the result obtained.We started sawing the aluminum profile.

Everything needs to be isolated.

Lens

The lens was attached to plasticine to adjust its position.

By the way, this lens works better if it is turned over with the convex part facing the laser diode.

We adjust and get a more or less collected beam.

It's probably possible to fine-tune it, but for us this was enough for the black plastic to start melting.

The match instantly ignited.

The black electrical tape was cut like a knife through butter.

This laser would make a great gun for playing toy soldiers.

![]()

Video

The video shows the speed of the laser's impact on some materials (a white sheet, writing on paper with a marker, black plastic and black electrical tape, thread, plasticine).DVD LASER "SMOKE"

Many people make all sorts of unnecessary but cool devices, and I was no exception. I decided, following the example of many, to make a laser from a DVD - a burning diode torn out of a non-working DVD burner drive. So, we ask our radio cat to help spin up the computer:

Then we remove the drive cover and take out the strip on which the DVD laser is installed.

To connect it to the battery, you can use a specialized one with current stabilization. But these microcircuits cost $5-10, and they burn out immediately if they are set up incorrectly! Besides, you can’t get them everywhere.Therefore, it was decided to make our own power supply scheme, which, as it turned out, works great,also together with a 220V charger.

Battery: nickel-cadmium fingers 3 pcs or lithium-ion from a mobile phone. So let's get started, take a diode from the divider -

They say they are afraid of static, but I didn’t take any protective measures and still didn’t burn. But when the current increased above 0.3A, they flew out instantly. I burned four of them! Let's shove all this DVD laser in some suitable case, for example a Chinese lantern,

I first took the lens for focusing from the same DVD drive, but as it turned out, the laser does not work well with it - focusing is no good. I had to go to the market and spend a dollar to buy a laser pointer. Her lens is just super - it focuses to the point.

And besides, it attaches conveniently! As a bonus, we have three 1.5V button batteries, a button and a very bright red LED. In front of the flashlight, instead of glass, we put a round piece of plastic with a 10 mm hole for the beam. That's all, combat laser from DVD "smoke" is ready!

Lights matches within 1 meter, makes wood, rubber, plastic, black paper smoke well. Current consumption is up to 0.3A, but I recommend not setting the limit, but reducing it to a safe 0.2A. It will be even better if you power it from an ultra-low voltage drop - 0.05V.

For any questions write to

In chapter There are vacancies for photographs of your lasers and other devices!

I remember about 10 years ago, it was popular among beginning radio amateurs to make lasers from a DVD drive diode that burns discs. Despite the primitiveness of the design, with a blue laser diode it was possible to obtain a power of up to 0.6 watts, powering this thing from batteries. But the Chinese industry does not stand still and now it is no longer possible to cut foil on a CD, but wood and even metal using powerful modern laser modules of 1-15 watts. All of them are designed for use on CNC machines () and are powered by 12 volts. Naturally, they can work without mains power - on 3 lithium batteries, which allows these laser modules to be used... let's say - not only in machine tools))

But let's move on to the review. Modules of 1, 5, 10 and 15 watts will take part in it. Let's start with the youngest one, which is installed in .

1W laser head

Laser from China 1 watt

Laser from China 1 watt - Wavelength 410 nm

- Output power 1 W

- Supply voltage 12 V

- Operating current 400 mA

- Cooling method: forced air cooling

- Case material - aluminum

- Optical lenses in laser

- Operating temperature 40-75C

- Service life up to 10,000 hours

- Size 33 x 55 mm

- Price about 50 dollars

5W laser head

Laser from China 5 watt

Laser from China 5 watt - External dimensions: Length 53 mm x width 33 mm x height 33 mm

- Wavelength: 450 nm

- Output power: 5.5W

- Cooling: Aluminum radiator

- Modulation frequency: maximum 25 kHz

- Finish Color: Black

- Housing material: Aluminum

- Operating voltage: DC=12V

- Operating current: I< 3 A

- Warm-up time: No

- Operating temperature: -10~+40 degrees

- Price about 120 dollars

10W laser head

Laser from China 10 watt

Laser from China 10 watt - External dimensions: length 50mm x width 50mm x height 100mm (including fan)

- Wavelength: 445-450 (Blu-Ray)

- Maximum power: 10 W in pulsed mode

- Average power 6 W

- Modulation frequency: TTL can be modulated

- PWM frequency< 9 кГц

- Operating voltage: DC=12V

- Working current:< 3 A

- Focal length: 18mm

- Working temperature: 15~45C

- Spot diameter: 0.1 – 10 mm

- Operating mode: pulse laser 100 ns 50%, with TTL modulation

- Body Material: Solid Aluminum + Brass

- Finish: Black anodized Al + sandblasting

- Heat sink: heatsink and fan

- Power supply: 12V 4A

- Price about 240 dollars

15W laser head

Laser from China 15 watt

Laser from China 15 watt - Laser model: 570073

- Size: length 50mm x width 50mm x height 100mm

- Wavelength: 445~450nm

- Output power: pulse 15 W, average 8 W

- Modulation frequency: TTL modulated, 0V-off 5V-on

- PWM frequency<9 кГц

- Operating voltage: 12V

- Operating current: I<5 A

- Operating temperature: 15-45C

- Focal length: 18mm

- Power supply: 12 V 4 A

- Price about 320 dollars

In appearance and design, the 5-15 watt models are very similar, so without markings or tests it is difficult to immediately determine the power.

Laser connection diagram

Laser module power supply circuit

Power supply circuit for the laser module in the CNC

The modules are connected to a 12 V DC voltage source, differing only in current consumption. On the machine, a special connector on the CNC board is used to supply power, and if necessary, you can use a regular switching power supply by plugging the plug into a standard socket through such an adapter (included in the kit).

Adapter for external laser power supply

Adapter for external laser power supply TTL control is carried out through a special block using PWM pulses. There is no schematic, but here is a photo of this board with parts in good quality.

TTL PSU board

TTL PSU board How to choose laser power

With the most powerful head available, the 15-watt head, you can easily engrave not only wood, but almost any type of metal (some are better at burning, others worse). With a laser up to 5 watts you can engrave and cut wood, cardboard, plastic, and leather. Well, the 1-watt model won’t surprise you with any special results - only cardboard and plywood.

Laser cutting - examples

Laser cutting - examples Note:

The head will output 100% of the laser intensity when you directly connect it to a 12V power source. Do not use it for more than 10 minutes in this mode, otherwise the laser will burn out. It is advisable to slightly reduce the supply voltage, at least by 1 volt - this will significantly increase the life of the diode without a noticeable decrease in beam power.

Making a Smart TV if you don't have one

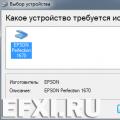

Making a Smart TV if you don't have one How to scan in Photoshop cs5

How to scan in Photoshop cs5 Cropping an image in AutoCAD if there is nowhere to go and there are no other tools

Cropping an image in AutoCAD if there is nowhere to go and there are no other tools