Program for compiling carding cards. Programs for cutting chipboard

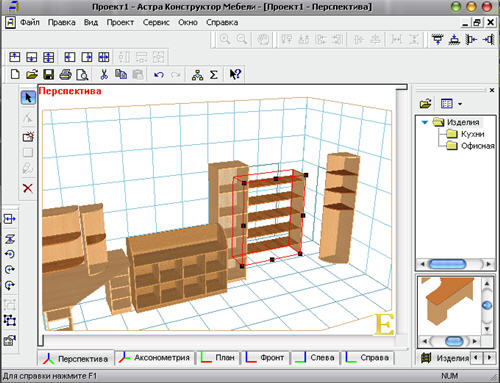

For the cutting chipboard, it is recommended to draw your attention to the Astra utility to cut and download it. This is an excellent application that copes excellently with all its functions and options. At the same time, the program is different from our usual service and office applications. If you download Astra free, you should know that the software is designed to work in companies engaged in the manufacture of furniture to order. On medium and small enterprises free software For cutting chipboard will be indispensable.

Question may arise: why it is required to download a program for the cutting of the chipboard, because it is not very difficult to cut the sheets for construction decorative designs, most importantly, have certain skills in this work. In principle, there is a certain meaning here, but only in case of one-time work. However, professional users who work with such materials are constantly, free Astra Utility will simply need.

To the number functional features This application refers to the fact that the Software Software software allows you to work with a whole order in which there are many products that, in turn, consist of a certain number of parts. If you download the program for free, then you can keep your own spare parts, products and details library. Such a function will be very useful for all users, especially if buyers choose to order typical parts consisting of standard spare parts. In addition, it is possible to end-cutting the warehouse of materials, in which case the sheets of the chipboard remaining after work are sent to the warehouse to perform the next order.

Excellent program cutting chipboard download free Astra cutting

Just just free download the Astra Cutting program to cut the chipboard to generate all the necessary cutting cards in automatic mode. Naturally, the program takes into account all the organizational and technological parameters of the order, for example, the minimum distance between the saws, the type of cutting, the accounting of through materials, trimming the edge of the sheet, the width of the cut and much more. If necessary, users can easily make certain adjustments without any problems, because for this there is a special editor of the DSP cutting card.

Another positive quality this application It is that the Astra is cutting can be used to calculate and analyze the production of edges of the material regardless of its nature. Accordingly, if you download software, you can get all the information regarding the production of furniture, cuts or grinding glass, as well as cutting edges for subsequent welding.

Carding card - is a documentation that displays which parts should be cut from the chipboard. But, in fact, you can not only cut the chipboard, but also any sheet material.

With the help of cutting, you can view how you can decompose the parts on the sheet. The map also has information about the remains that will be as a result of cutting.

As a result, the advantage of cutting is to display the amount of material that will be required to create furniture.

You can make a cutting chipboard in the firm where you will buy materials, but our task is to create cabinet furniture at home with minimizing costs, and it is not possible to make it possible, even a newbie.

To create a map, we will use the Cutting 2 program (Cattle). You can download it at the end of the lesson.

The program interface looks like this:

In the field of "Materials", you need to set the parameters of the chipboard sheet or if you have remnants that plan to cut out, then the size of the residues. As for the size of the chipboard, I use the SWISSPAN manufacturer's sheets, the dimensions of which are 2750 * 1830 mm (for large sheets) and 2440 * 1830 mm (for small).

Also note that in the settings of the chipboard sheet it is necessary to set the values \u200b\u200bof the "drew sheet", since the sheets initially have chips.

If you plan to glue the edge of PVC, or you want to calculate how much paper edges will be needed for a sizing, then you can also set it in the "properties".

Hello, friends.

In this article we will talk about one practical side of the manufacture of furniture.

After placing any furniture, you get its detail, or, a list of all the details necessary for its assembly.

And the next stage will be the purchase of chipboard sheets, and cut them into these most, you are designed details.

Here you can have two options:

Either you carry your detail to where you will be chipboard (and, it is basically the same place where you will buy it), and you will be done by your detail, saw the sheets of the material to the desired details.

Either you initially make a scheme for which sheet material will be processed.

Calling cards - and there is a layout diagram (for example, the same LDSP) for the necessary details.

Any such card always shows the presence of remnants of the material used.

The same details can be decomposed on the sheet so that in one case, the resizions of the residues will be large, and in another case, smaller.

Of course, you always need large remnants, as they can still be done about them.

Therefore, in the case when someone does this documentation, the dimensions of your residues depend only on it.

And if you do it yourself, then you have the items on it to get the most of the largest remnants.

Manually, of course, no one does, because it is very laborious.

For these purposes have long been invented very good programs.

But we will look at a simpler option: one source sheet of chipboard, and detail for it.

But we will look at a simpler option: one source sheet of chipboard, and detail for it.

Before making the calculation of parts, in the source sheet, you can set dumped over the ends (in this case, 7 millimeters).

Before making the calculation of parts, in the source sheet, you can set dumped over the ends (in this case, 7 millimeters).

After that, by clicking on the "Calculator" icon, the program will execute automatically parts according to the specified sheet.

After that, by clicking on the "Calculator" icon, the program will execute automatically parts according to the specified sheet.

As can be seen in the picture, even if any details did not fit into the sheet, they can be seen in the window below.

In this window, the location of any parts can be changed at your discretion, turn them around the axis (unless, of course, in the properties specified in the details settings, this function is not blocked). In short, to do everything to get the most remnants.

In this window, the location of any parts can be changed at your discretion, turn them around the axis (unless, of course, in the properties specified in the details settings, this function is not blocked). In short, to do everything to get the most remnants.

When the details are decomposed as you need, you can click on the view of this sheet.

In this mode, the location scheme of all parts is shown, the total length of propyl, the area of \u200b\u200bparts and residues, in one word, all the necessary information.

In this mode, the location scheme of all parts is shown, the total length of propyl, the area of \u200b\u200bparts and residues, in one word, all the necessary information.

After that, by clicking on the corresponding icon, all sheets with open, as well as a list of all parts can be printed on the printer.

After that, by clicking on the corresponding icon, all sheets with open, as well as a list of all parts can be printed on the printer.

This will be your cutting card (it still places a stick with a furniture edge, and sketches of non-standard (curvilinear, etc.) of details).

This will be your cutting card (it still places a stick with a furniture edge, and sketches of non-standard (curvilinear, etc.) of details).

Thus, as you can see, make the scheme of the saws of the sheets quite easily.

I believe it should be able to do the most ordinary furniture maker, since all this, in a sense, speaks about the level of his qualifications.

Well, on this I will "spin up," to the meeting.

This article is the logical conclusion of the article cycle about independent design and calculation of furniture for the house.

Here I will tell you how to make economical cutting at home, I will point out all sorts of nuances and possible pitfalls to which you should be ready, drafting to order cutting chipboard on furniture production.

FAQ or frequently asked questions

1 - Why do you do it yourself? - First of all, an independent cutting of parts in a sheet of chipboard is your savings.

The fact is that most furniture companies producing sawy chipboard are sold by the plates of the piece. That is, if the items that you need are not placed in the LSP sheet, and at least one thing turns out to be on the second plate, you have to pay for two complete chipboard.

Agree, it is not very profitable to pay two plates, if it turns out that on a wardrobe or kitchen is only a sheet of chipboard and a couple of small details.

That is why it is better to do it on home on home, according to which it can be ordered in a furniture workshop.

2 - What should I do if anyway on the discloser chipboard turns out a big balance? - Everything is simple - look back with a look of your apartment and a house. You may not hinder a small coffee table or bookshelves are needed.

Use the residue rationally, consider several new decorative and functional elements for the interior and add them to your cutting.

Thus, the purchase of details of the chipboard will turn from knowingly unprofitable in very economical and thoughtful.

3 - What is the structure of the LDSP? How to understand the expression of furniture makers - by structure or against the structure? - Pay attention to the coloring of the laminated chipboard, if there is a wooden drawing in it, it means it has a schematic image of this "structure", namely, the structures of the tree bark, imitating one or another breed (beech, ash, pine, oak, alder, cherry and others.)

Agree, Furniture facades look pretty stupid, in which the drawing (structure) goes aimbit - on one along, on the second across, then again along.

Therefore, before ordering LDSP in production, you must have a list of parts written according to specific rules and sequences.

So, pay attention to how the plate laminated chipboard looks like.

We see that the structure goes along the long side. And, if the details will fall parallel to the pictures - such a detail of the furniture makers will call "according to the structure", if perpendicular to the "against the structure".

4 - How to specify the dimensions in the list so that the details of one species have the same pattern of the structure? - The first and most important thing is to determine the visible elements on which the structure is obliged to be located in the same direction.

For example, facades, cabinet sides, facial base. But those details that are located inside the cabinet (internal shelves, sides of drawers and the like), can be cut from the LISF LISF.

Specifying the dimensions for the furniture workshop, it is better to clarify in advance where you plan to produce broken LDSP, what size of the part to specify first.

In most furniture companies, the first indicate the size of the part that goes according to the structure, that is, along the drawing.

And now carefully review the schematic sketch, located below - on it, I tried to portray as much as possible how the parts in the sizes of the structure mentioned and against the structure will look.

5 - What is the LDSP sheet bazing? Why, with independent, laid part of the DSP specify the size of the slab less actual? - Indeed, knowing the standard dimensions of the leaf of the LDSP, creating cutting, you need to consider the leaf-based leaf, which will necessarily do in the workshop before cutting parts.

Usually, the edges of the plate contain some chips, irregularities, perhaps even a small swelling. Therefore, the sawers "basize the sheet of chipboard" - cut 10-15 mm on each side. Based on this, you should also make a basing, that is, to take for the right size, for example, not 1830 x 2750 mm, and 1810 x 2730 mm.

6 - What is the width of the cut, and what is it equal to? - The width of the propyl is the width of the cut of the saw. The saw installed on the sawing machine has a thickness of 4 mm, which means there will be a thicker to these same 4 mm between the details.

That is, the actual size on which two parts 300 and 400 mm will be located - not 700 mm, and 300 + 400 + 4 \u003d 704 mm. Each propyl needed also be sure to take into account when striking.

Well, that's all, now you are prepared in order to proceed directly to the independent disclosure of the details of the LDSP, which can be made in two ways - manually, using a ruler, leaflet, elasty, calculator and using a computer offline or online programs Cutting.

Manual cutting details of chipboard: step-by-step instruction

1 Cutting on a sheet of paper, preferably on the scale, size of the plate. Do not forget to reduce it on each side by 10 mm.

2 Sort the list by the same features of the necessary parts. For example, the base of kitchen cabinets have the same dimensions - 500 x 712 mm.

They are quite a lot, write out all such details separately. The same principle continues to sort: the same width, the same structure, and so on.

3 lay out on a sheet of chipboard first large details and those that should have a similar structure. Do not forget about the width of the saw - 4 mm! Here you will definitely use the calculator.

4 Place the remaining details. You can work out several options until it turns out the very ideal, the most economical and profitable.

Cutting parts in LDSP sheet with computer online and offline programs

On the Internet, in free access, there are many programs for the creation of chipboard, which offer several options at once.

Such programs can be searched for specialized furniture forums or just scoring in any search engine Request: "Cutting the DSP Cutting Freewher."

Search will issue three main options:

1 Download the screening program to the computer is the most common and most convenient for beginners. Cutting LDSP - Cutting. A simple interface, a clear layout and a plurality of saw cutting options.

2 Create a DSP screening online - here you will not need to download your PC programs that may be in the future and will not be useful.

3 cutting and ordering dsp online on the furniture company's website - the perfect option, if the production workshop is convenient for you geographically.

Thus, you will kill two, and maybe more, Zaitsev "- choose LDSP on the site, which is available in the required quantity, make an economical cutting, see the cost and immediately, sitting at home, order sawing chipboard in the furniture workshop.

I repeat important moments again ...

Basic Rules Cutting DSP

- The size of the LDSP sheet must be administered with the base of the plates.

- Width of the cutting saw - 4 mm.

- Details in cutting should be made based on the structure.

If you have any questions - ask them right here, under the article. I will try to respond quickly.

Also, if there are current furniture topics that you would like to read - write about them in the comments. Perhaps this is exactly what will push for writing the next article.

Always yours, Timur Denisov.

Download outdoor

Cutting 6.54.121- Interesting and the necessary program With the ability to build a card cutting various industrial materials. For example, cutting chipboard, glass, plastic, rolled materials and sheets.

The main "chips" of the program:

- Work begins in the appendix from the introduction of the concept of "order". It is believed that this is a complex of details with specified height and width parameters. Details are set rectangular shape.

- You can specify the desired number of parts in the order. At the same time, the program will issue the optimal number of sheets that must be purchased.

- It is possible to view the history of orders, changes already completed or repetition with new parameters.

- For each individual item, it is possible to set a symbolic name, the number of these elements and the presence / absence of the edge (in particular, in the production of furniture shields).

- Along with standard sheets, it is possible to introduce additional sheets and conduct their cutting next to the main.

- You can specify the magnitude of "business waste" for subsequent application. This is possible under the condition of large, mass production.

- You can specify the size of the technological waste, for example, the consumption of material on the cut.

- When calculating, it is possible to combine different orders from the same material. Thus, it is possible to save on a string.

- In a free cutting program, you can work with two types of edges.

- The incision is made by the guillotine method, that is, from the edge to the edge. All cuts are smooth, strictly vertical or horizontal.

- There are two ways to cut in the program: minimization of total waste (maximum material use ratio) and maximizing continuous trimming (minimum waste plus maximum business trim).

- When laying out the material in the roll, the program on the machine is able to select an option for placing elements on the tape. All items will be rectangular and unknown height.

- There is an opportunity to use the cutting program in network mode.

- There is no language barrier, since the program in Russian has been released.

- The interface is simple, in calm colors, like any other graphics program.

- Operating systems for which the program is suitable: WindowsXP, WindowsVista, Windows7.

The cutting program of sheet and rolled material is used on various technical and industrial production, factories, factories, as well as in small enterprises. In domestic conditions, with this program, you can make calculations for the construction of a garden or bath, repairing the interior or facing at home. Cutting 6.54.121 will provide a high-quality and fast calculation of the material. Most often, the application is used to calculate the chipboard and glass.

Where can I download the program safe and free.

Program download free Hurry from Softldol.com. It is available for a direct link without registration and paid messages.

Version:6.54.121

Program status:Conditionally free

The size: 3.5 Mb.

Developer:Andrey Kusnetsov.

System: Windows 7, 8, XP, Vista

Russian language:Yes

Download 6.54 Free Download

At first I used the Cutting 2 program, then Cutting 3. They differ quite strongly. But the version of Cutting 2 I liked more. In the third version there are additional featureswhich by and large is not very necessary for small production. Cutting 2 and now helps me in the preliminary calculation of the amount of material and the length of the cut line for large orders, such as the kitchen. To create a final cutting card, I use the NOWY ROZKRój (Cut Optimiser or New Cut Manager) program from the creators of the PRO100 program. . Both sites can be switched to Russian and familiarize yourself with the description of the programs. And now I will describe the uncomplicated process of creating carding cards. .

Open any project created by us in Pro100. Click on the Σ tab.

The table opened will reflect the table in which all project elements will be indicated with their characteristics. At the bottom of the window we find the Copy All tab.

Click on it. Now we can insert a table with our elements in the list of parts in Cutting 2. But we need only elements of the main material, let's say the chipboard thickness18 mm. Therefore, open Excel and insert the list of Pro100 elements. Now we allocate those lines in which the elements are not 16 mmi remove them. As a result, there remains a table consisting of 4 columns, in one of which in all cells only number 18. We allocate and delete this column. The remaining items allocate and copy. Run the Cutting program 2. Details table on the right.

If it is not empty, click on the x icon over the right table and confirm the cleaning of the list. Now click on the right key on the first empty list of the list and in the drop-down menu, select the line to add from the clipboard.

Click on the execution icon.

Card cutting ready. You can print and use. But I ran into some inconveniences. For example, numbers are small, the cut line is not clear enough.

People who cried material for me were unhappy with the need to use magnifying glass. But for the preliminary calculation of the cost of the product, the program approached ideally due to the above-described part of parts from Pro100 in Cutting 2.

NOWY ROZKROJ program is a better optimizer.

But all the dimensions of the parts must be administered manually.

The program calculates several cutting options at once.

Depending on what is important to you, you choose your own option. It is more suitable for me with a smaller total long cut line, and someone needs a variant with a smaller number of cropping (trash).

First, in the settings, I specify the option of cutting without a strip,

which allows you to place a greater number of details. After the first attempt to cut, I see a lot free space It remains on the last sheet. If more than 30% are not occupied by the details, then in the program parameters, I specify the version of the horizontal

and launch the final calculation. The remaining horizontal bandwidth of the material of the material seller leaves itself, which reduces the cost of furniture. Calling cards created by Nowy Rozkroj program are sufficiently detailed and distinct, dimensions are displayed perfectly.

The result of cutting can be different. For example, you made the optimal cut when an option without a strip, and you have 3 sheets and 3 details. This is especially important if this color of the material seller does not sell the stripe, but only a sheet. In this case, apply the following option:

When adding each part, remove the mark in the table properties table on the structure position.

Then, looking at your project, go through the detail and mark the structure in detail, the structure on which can only be aware of the design, i.e. Other structural options on these parts are not acceptable. If this method does not help, then reduce the size of hidden parts, such as grounds and connecting strips, 10, or more, mm. But do not overdo it.

There is another important plus from this program. If you marked the edge on any side of the part, then it will not eat from this side to another when you turn the part with the optimizer, which can happen in other programs. In the event that the end edge is paper, the dimensions of the parts remain the same as in the project, and if the PVC edge is 1-2 mm thick, then do not forget to take away from the size of the adjacent side with the edge thickness of the edge.

Example of cutting cards

At the beginning of the roller, until the start of the program of Nowy Rozkró, do not pay attention. And then all on the topic. A small technical hitch.

If your sheet, for example, 2800 at 2070, and trimming on the side of 10 mm, forgetting that 4 mm is needed on the cutting, you specify the size of the part 2790 to 600 with the edge of 2790. As a result, the edge slides on 600. Please note This is attention. I once did not check the card and gave it to work. First, the guys suffered when the edge was glued to the side 600, because The detail rested in the door of the workshop, had to move the machine. No one thought that the distance from the machine to the wall 2.5 m may be ever sufficient. And secondly, I had to pay for me to shove the edge along the long side, and at that moment I did not count on it. Therefore, be careful.

Automated production system Practicam ™ Focused on the production of products for ventilation systems from sheet and rolled metal, as well as from pipe blanks. Practicam ™ Works with plasma and laser machines with numeric software control (CNC), as well as with stamping, spiral and coordinate-cutting machines. The program has great functionality For cutting sheet metal, i.e. It is focused not only on the production of air ducts, but also flat parts, signs, flugers, roof elements, etc.

The main advantages of the Practicam ™ system:

|

Creation of ducts of any type, as well as any other elements from sheet and rolled metal, and tube blanks |

| System libraries Practicam ™ Very extensive and have no equal. They contain more than 4,000 fittings and more than 1600 parameterized flat parts. Despite such diversity, system library Practicam ™ still increase (every time you download the new version of our program you will be waiting for new elements). In addition to existing libraries, we can create so many different fittings for you, flat details and other elements as you wish. We will make the details you need and send them them in the shortest possible time (as a rule, the development of a new part, depending on its complexity, takes from one to three working days). |

|

|

Compatibility with any equipment |

| System Practicam ™ Supports many models of plasma and Laser machines with CNC. It can also work with stamping, spiral, coordinate-cutting machines, pipe cutters and bar code reading devices. If your model of the machine in our library is not yet, then we will write a postprocessor for you in the shortest possible time for you, which will connect our program with your equipment. | |

|

Instant and accurate estimation of expenses |

| During your work system Practicam ™ Continuously creates an accurate estimate of the cost of all costs for the manufacture of parts. Full calculation takes into account the value of the material, labor costs for the manufacture of parts, the cost of all fastening elements (bolts, screws, tires, ripples, etc.), as well as the cost of various accessories (blades, rods, dampers, etc.). As an example, American SMACNA Standard Tables are given, but you can create your own regulatory tables for accounting for labor costs at your enterprise, taking into account the specifics of your production. | |

|

Export and import information into generally accepted formats.dxf, DWG I.CSV for communication with software products 1C, Microsoft, Autodesk |

| All information about the expended metal consumables and components contained in the system PRACTICAM ™, It can be translated into a format file.CSV, which is supported by 1C: Accounting and Microsoft Excel. This makes it possible to calculate the value of all your products using accounting programs. System Practicam ™ knows how to work with format files.dxf i.dwG, which allows you to import drawings from autoCAD programs and a compass, as well as export to these programs, cutting, patterns of fittings and flat parts. |

|

|

Import orders from the program 1C: Accounting |

| In the program 1C: Accounting, you can form orders for cutting fittings, indicating the names of fittings, their number, the material from which they should be made, technological parameters, points name, etc., and send them to the system Practicam ™. Having received an order, system Practicam ™ Automatically finds these fittings in their libraries, applies the specified parameters to them and lay out the patterns of the fittings on metal sheets. After automatic laying, control commands are generated for your equipment, as well as various reports and labels. | |

|

Metal savings |

| It is possible to use sheet metal residues suitable for cutting out any products, and the maximum use of the sheet area. To do this, a functional module "Warehouse" has been added, which allows you to automatically add flat parts from a previously created list to the sheet metal, after laying on the metal sheets of metal. | |

|

Ability to automatically laying products using a combined cut |

| IN Practicam ™ There are two options for automatic laying of products: normal styling and laying with a combined thumb for products that can be combined by one of the sides. | |

|

Fully Russified |

| In addition to the Russian language, system Practicam ™ Translated into English, French, Spanish, Chinese and Korean. | |

|

Various types of letters |

| Power supply (connectors, locks, joints, seams) and notches contained in large quantities in system libraries PRACTICAM ™, Can be created in any geometrical form, completely parameterized and available for editing. Graphics editor Provides ample opportunities for creating and editing spaces and notes. | |

|

Creating reports |

| System Practicam ™ Provides you a wide selection of typical templates for reports. Additionally, you can create your own reporting forms in any convenient format and with any type of layout. The main thing is that in the report you can inform any information contained in the system Practicam ™. | |

|

Creating labels |

| Mark the details in the system Practicam ™ Easy and convenient. Various label templates are provided to your attention, but if they are not satisfied with something, then you can create your own template. Add any information to your labels: the logo of your organization, barcodes, 3D images of details, any part parameters you are interested in; Edit these inscriptions in any style and font size. You can make a label for any fitting and flat details. | |

|

Useful specifications |

| Specifications (Slug) System Practicam ™ Allow all the features of your production standards when working with various products, allowing you to unify production, automate the production of products for making and reduce the number of errors when entering, thereby increasing your performance, and with it and profit. You can create your own rules for the production of products that are used at your enterprise. | |

|

Having libraries of double-wall fittings |

| In system Practicam ™ There are libraries of double-wall fittings. They are used in cases where it is necessary to increase the level of heat and noise insulation. For each double-wall fitting, you can cut insulation, which is stacked between its walls. | |

|

Possibility of manual and automatic segmentation for large-sized products |

| System Practicam ™ Allows you to segment (split into separate components) of the product big sizewhich are not placed on a metal sheet. You can specify the segmentation rules for each product or entrust this program program. |

The advantages of our technical support:

- The best support of the product - at the request of users we develop and add new software modules, Create new fittings and parametric flat parts (within 1 - 3 days, depending on the complexity of the product), add to the already existing new ways to cutting fittings.

- Free education Working with the program.

- Regular update Practicam ™ - The new release goes no less than 1 time in 2 weeks.

- Development and addition of new labels and reports, placing information on them necessary to the user.

Currently developed a new version programs Practicam ™. Its main difference is that now the program is divided into many functional modules that can be turned on and off in different combinations, reducing or increasing the set of functions performed by the program. Depending on the number of connected modules, the price is formed. Practicam ™ still can be purchased entirely with all its capabilities, but you can also buy either one of the standard program packages (each of which is a truncated version of the system Practicam ™), or a standard package with additional options.

Standard packages Practicam ™:

Practicam ™ for typical parts.

- Use the libraries of parametric flat (two-dimensional) parts, create flat parts using a graphic editor.

- Work with graphic model Details, set dimensions, material and thickness.

- Use several layers when creating the part.

- Import files with extension.dxf, .dwg (AutoCAD systems, compass, etc.).

- Apply automatic laying of parts on metal sheets using various algorithms, including a combined cut.

- Stop metal sheets manually.

-

at the exit).

PRACTICAM ™ for ventilation.

This package allows the user:

- Use link libraries (fittings).

- Work with a three-dimensional graphic fitting model, set sizes, allowances, material, determine the method of cutting fitting.

- Working with the library of accessories of fittings, set the valves, ribs of rigidity, ties, swivel blades.

- Use various labeling excavations, automatically form the lines of the gib, create labeling lines.

- Create a library of materials used indicating the thickness of the material and type (sheet, roll).

- Create a library of battles used (connectors, locks, joints).

- Apply automatic laying of articles of products on metal sheets using various algorithms, including a combined cut.

- Stop articles on metal sheets manually.

- According to the laying results, form and print laying cards.

- According to the laying results, automatically generate the sequence of control (CNC) commands for the cutter.

- Set the cutter parameters (table size, positioning and orientation of the table, size and form of cutting and cutting

at the exit). - Determine the transmission method on the cutter of control commands (through a file or som port).

- Automatically segment (cut into parts) Large pattern patterns.

- Automatically add allowances for segmentation segmentation.

- Create and edit allowances connecting segmented parts of the patterns.

- Create tables to recalculate the parameters of the fittings and apply them when creating fittings.

- Import / export files with extension.pmx (Practicam ™ program files).

Practicam ™ Classic.

This package combines PRACTICAM ™ packages for typical parts and "Practicam ™ for ventilation" and provides all the features listed for these packages.

Scroll additional options (Program features) for packages is shown in the table.

If you want to learn more about Practicam ™, then we can specifically for you completely free when help Skype Or TeamViewer to demonstrate the program's work at a convenient time to you, at the same time answering all your questions. Also, especially for your Machine Controller is completely free at your request, we can write a postprocessor and activate Practicam ™ for you for 1 month so that you can appreciate all its capabilities directly in your work. All that is needed for this is to call us or write a message to our emailOr leave your contact details by filling out the following form.

Cutting - a program for cutting sheet materials: wood chipboard, glass, etc. The DSP cutting program makes it possible to reduce and optimize the consumption of the material, it makes accounting for waste, including "business", which are not taken into account when calculating the order value. The utility can be used in enterprises engaged in the mass production of cabinet furniture, for this in its functionality, the concept of order has been introduced. All executed orders are automatically recorded in the order base, subsequently it is possible to repeat or change them. Download free Cutting You can on this site.

To start working with the utility, you need to set the size of the sheet and parts that will be cut out of it. Next, the program will independently select the optimal version of the cutting with the lowest amount of waste. If necessary, you can use the database of materials available in the program, in which the standard dimensions of sheets or rolls are laid. In this case, it is enough to specify the material for cutting, and the utility will automatically make a calculation according to the standard sheet parameters.

The program for cutting works on two basic algorithms for optimizing the DSC flow rate - a decrease in overall waste and an increase in continuous cropping. A decrease in overall waste involves cutting with a minimum amount of cropping. The mode of increasing continuous trimming, in addition to reducing waste, is used to create maximum trimming, which can then be used for another order. You can also save on the material by combining two orders if the same material is used for them.

The main advantages of the utility cutting

- Two cutting optimization algorithm.

- Database of standard sheet size.

- Work with two types of edges.

- Work with both sheets and rolls.

- Database of completed orders.

During the cutting, all the cuts are produced from one edge of the sheet to another - either horizontally, or vertically. The material consumed on the cut and other technological operations is taken into account when calculating the cutting. The utility allows you to work with two variety of edges. The program allows you to optimize the consumption of not only sheets, but also rolls. If necessary, it is possible to use the cutting in the network mode.

If we talk about sawing wood-sheet programs (chipboard), i.e., many programs cutting sheets of wood chipboard, you can apply "Pro100 cutting".

In a furniture business, a fairly important role is played by the program of sawing sheets of a chipboard, because the correct sawing of the sheets of a chipboard is one of the most important qualities, in the manufacture of furniture.

Book Crack LDSP now! ...

It is not difficult to determine the quality of cutting: if there are no chippers on the blanks, it can be concluded that the cut is made as it should. In the furniture business, much attention is paid to the cutting of sheet materials. Products made of chipboards are not very good, if there are traces of sawing on the visible side.

For today, everything is automated in the furniture workshops. For example, a number of machines are used on production, which are quite successfully coping with this task. These include equipment of the type of formatorship, additive and edge-bullshit machines.

To cut the chipboard soon, the specialists use the cutting program, such as Pro100 cutting.

Pay attention to the sawing sheets of the wood chipboard on the Festool cutting machine. If you take, let's say, LDSP, then it is better to use a format cutting machine, as it is convenient to cut down the LDSP (you can write down from hundred sheets per day). As for the pricing policy, it depends on the company that offers this service.

For cutting sheets of wood chipboard, you can also use the Festool immersion saw. It is not a very expensive option. Due to the fact that the above-mentioned saw is not bad ratios in the price category + quality, this option is popular. There is still the following programs to cut the chipboard, which cost to pay attention.

Consider them in more detail:

"Basis-cutting" They are unique, modern programs, with a visual and understandable interface and has a powerful mathematical algorithm for the optimal cutting of any materials used on furniture production. These Basis-cutting programs are included in the complex-furniture complex.

The next breakfast program, which is also popular - Cutting.. It is intended to optimally cut the material on the details, depending on which it is necessary. If a rectangular item is needed, this program will help make such a detail if the linear one is needed, the linear is separated. This program is used not only for woodworking, but also for the production of furniture, metal cutting, and so on. Thanks to the high-grade algorithm that is in the program, cutting with minimal waste.

One more interesting program Cut is a program Astra-D.. It is intended for the purpose of the automated cutting of the chipboard. Also, it is used with strollers and other materials, such as plastic, glass, metal and others. In addition, the Astra-D program improves efficiency and reduces the time that is spent when the cutting card is formed. The program is designed for operational windows systems. The user will be able to master the work in this program and simply understand the menu system.

Now consider the program Bestcut.. This program facilitates the tasks that are associated with the sawing of the chipboard, the calculations of the price of materials and work. With its help, you can get a scheme for cutting a wood chipboard and equipment that will be used with this procedure. Also, this program will allow you to get accurate cards of cutting sheets of wood chipboard to rectangular parts. Not an unimportant fact is also what the features of which will have to face in the process of processing sheets of wood-chipboard are taken into account. Work can be supported through local network, and this is also convenient enough.

State Services Personal Account

State Services Personal Account State Supervisory Cabinet- Entrance on SNILS and Telephone

State Supervisory Cabinet- Entrance on SNILS and Telephone Single telephone rescue service in the Russian Federation

Single telephone rescue service in the Russian Federation